Defintion of Poka-Yoke

Poka-Yoke is also called foolproof method or mistake-proofing which means to prevent process errors before they occur. It is a method that uses automatic actions, alarms, markings, classifications and other means during the operation process, so that the operators won’t make mistakes even if the operator doesn’t pay special attention.

Purpose and Function of Poka-Yoke

Poka-Yoke is the most important part of implementing lean production. During the operation process, operators will occasionally make operational errors due to omissions or forgetfulness, leading to high proportion of quality defects. If Poka-Yoke can be used to prevent such mistakes, the quality level and work efficiency will be greatly improved. At the same time, it will be of great help to reduce waste, reduce costs and improve employee confidence. Because Poka-Yoke means "doing things right the first time, using a series of methods and tools to prevent errors from happening. Because doing things right the first time, the direct result is the improvement of product quality. Compared with relying on inspection to ensure quality, Poka-Yoke is a preventive measure taken from a prevention perspective (inspection cannot prevent the occurrence of defects, defects found during inspection can only be corrected, which is a waste, error prevention eliminates this waste). Poka-Yoke will improve the product quality, eliminate defects, which will lead to the reduction of rework times and reduce the time and resource waste of rework.

Main Types of Error

Improper product design: ① Positioning of technical attributes of the product. ② Product usage scenario positioning. ③Reliable and safe positioning of products...

Improper production and manufacturing process: ① Missing a certain operation step ② Operation error ③ Setting error ④ Missing parts ⑤ Using wrong parts ⑥ Workpiece processing error ⑦ Mis-operation ⑧ Adjustment error ⑨ Improper equipment parameter setting ⑩ Improper preparation of tooling fixtures... .

Improper use by users: ① Improper use environment ② Improper use method ③ Improper use time...

Main Forms of Errors (Mistakes):

Unintentional errors: Mistakes that occur unconsciously due to lack of concentration during repetitive tasks.

They have four distinctive features:

① Simple work is not done well with errors occur;

② Errors caused by numbness when working repeatedly for a long time;

③Unintentional errors occur, usually caused by ambiguity in the work process (or work standards);

④Once an unconscious error occurs, it is difficult to find the reason for the error based on daily experience.

Error: The action (or step) performed is inconsistent with the expected action (or result), which mainly manifests nine characteristics:

①Forgot: That is, forgetting the work or inspection steps.

②Not familiar with the process/job: Not familiar with the job process or steps.

③Identification error: Misjudgment or misunderstanding of work instructions and procedures.

④Lack of work experience: Due to lack of work experience, it is easy to make mistakes.

⑤ Intentional error: For some reason, the operator intentionally caused the error.

⑥ Negligence: This type of error is caused by the operator's carelessness and a large part of the errors are caused by such reasons.

⑦ Slow action: Errors caused by the operator’s slow judgment or decision-making ability.

⑧Lack of appropriate work guidance: Mistakes occur due to lack of work guidance or improper work guidance.

⑨Emergency: Due to emergencies, workers are caught off guard, resulting in errors.

Error prevention ideas

① Produce only the products needed

It has two meanings. One is to only produce the required quantity of products. Producing more than required is not only a waste, but also increases the chance of errors in all aspects of production, transportation and storage. Second, we need to keep in mind the customer's quality requirements for the product during production, so that the work meets the requirements. If it deviates from the customer's needs, there is no way to talk about quality and of course mistakes are frequent.

② Reduce, simplify, and merge work steps

The more work steps there are, the more opportunities there are for errors to occur. Cutting, simplifying and merging work steps is equivalent to creating conditions for reducing errors. In the new product development stage, adhering to this principle when designing the production process can greatly reduce defects in subsequent production. Applying this principle when analyzing and improving existing processes will also reduce the chance of errors.

③ Involve everyone in defect prevention

Quality can only be achieved with the participation of all employees. This has long been a consensus. Only when everyone participates in prevention can zero errors and zero defects be achieved.

④ Pursue perfection

Continue to pursue quality, cost, delivery, technology and service, such as "zero defects" in quality. If the company culture believes that zero defects are unachievable, it will undoubtedly condone "No one is perfect and it will be okay to make one or two mistakes." "What a big deal" and other views and the consequences can be imagined. Concepts will directly affect people's actions and establishing a culture of continuous pursuit of perfection is the fundamental guarantee for error prevention.

⑥Design systems and procedures to eliminate opportunities for defects to occur

The best system is prevention, the best quality is without inspection and testing. If a special system is designed to prevent possible errors during design and the probability of errors is completely eliminated, errors and defects will naturally disappear. This is the goal that quality engineers strive to pursue.

⑦Traceability testing

Traceability testing is to detect and confirm the operating conditions of the process to ensure that the conditions required for high-quality production are met before operation. For example, the design data review and measurement system evaluation in the new product development is traceability testing. Traceability testing is a preventive testing in the true sense. It ensures that the product and manufacturing process design can meet quality requirements by testing at the source, that is, at the time of design. According to the principle of quality leverage, the income from testing at this stage is a hundred times higher than that of judgmental testing. Currently, many companies have realized the significance of traceable testing and have begun to explore and implement traceable testing.

⑧Self-check

Self-inspection is an inspection and verification after the operator completes the work and puts the product into the next work station. It is part of the operation. Each product is 100% inspected. This is a good working habit. It is necessary to grasp the standards according to the requirements of this operating instruction and have a complete system to support it when conduct self-inspection.

⑨Mutual inspection

Mutual inspection is to verify the accuracy of the results of the previous process before the subsequent process. It can prevent losses caused by the accumulation of defects and is also conducive to building the teamwork spirit of the workers. It is one of the enduring error-proofing method.

Error Prevention Tools

①Special error-proofing tools and instruments

Refers to the use of specialized error-proofing tools, instruments, software, etc. to prevent errors from occurring.

② Streamlining the process

Process streamlining is a mistake-proofing tool that reduces, simplifies and merges work processes and work steps to reduce the chance of errors.

③ Statistical process control

Through statistical process control, special variations in the process can be discovered in real time, which is conducive to implementing improvements as soon as possible and minimizing losses. Statistical process control is also one of the error-proofing technologies currently used.

④Online test

Online testing is a mistake-proofing method that adds inspection and testing procedures to the work process to discover defects and prevent defects from leaking to customers or subsequent processes. It is one of the most common error-proofing methods that has been inherited. Almost all manufacturing processes use online testing for quality control to varying degrees.

⑤Use pass/stop/pass measurement tools

Pass/stop/pass type measurement tools can quickly determine whether a product is qualified. Compared with obtaining continuous data through measurement, pass/stop/pass type measurement tools are more efficient, low cost, accurate in judgment, and basically do not increase the burden on operators. This makes 100 % checking becomes easy and this is one of the mainstream methods used by many companies.

⑥ Confirm the approval process

Confirmors and approvers can review the work results from different angles, making it easier to find problems. For example, before a company's new product sample is released for production, the production staff will submit it to the senior management for confirmation and approval. Only after it is confirmed correct can it be released. This makes it easier to prevent the spread of mistakes and losses caused by errors.

Concepts that should be adhered to in error proofing

①Self-check and mutual check are the most basic, primitive but most effective error prevention methods;

② Poka-yoke devices do not require a large amount of resource investment or a high technical level but they must be arranged effectively;

③Any operation or transaction process can prevent human errors by incorporating error-proofing technology into the pre-design;

④ Through continuous process improvement and error prevention, zero defects can be achieved;

⑤ Poka-yoke should be based on prevention and error-proofing methods during each process operation should be considered during design;

⑥Consider error-proofing methods in all places where problems may arise.

Error Proofing Steps

Step 1: Determine product/service defects and collect data;

Step 2: Trace the defect discovery process and production process;

Step 3: Confirm the work instructions for the defect generation process;

Step 4: Confirm the difference between the actual work process and the work instructions;

Step 5: Confirm whether the following problems exist in the process:

1. Whether the process is being adjusted;

2. Whether the working tools or equipment of the process have been changed;

3. Whether the specifications, parameters and operating standards of the process have changed;

4. Whether there is mixing of products or excessive stacking;

5. Whether the process operation steps are too many or the workload is insufficient;

6. Whether the process operation standards are sufficient;

7. Whether the process operations are balanced;

8. What is the working environment of the process?

9. Whether the process rhythm is consistent with the site;

Step 6: Analyze the cause of the defect;

Step 7: Analyze the reasons for work errors;

Step 8: Design error-proofing devices or error-proofing procedures to prevent or detect similar errors;

Step 9: Confirm the error-proofing effect and make process adjustments if necessary;

Step 10: Continuous control and improvement.

Ten Principles of Error Prevention:

1. Root-clearing principle: Find out the root cause of the error and take corresponding preventive measures.

2. Insurance principle: Prevent erroneous behavior through insurance devices.

3. Automatic principle: Use automated methods to ensure that production is carried out in a predetermined manner and to avoid human errors.

4. Matching principle: eliminate the possibility of problems through simple methods such as shape, color, mark, quantity, etc.

5. Sequence principle: For processes with sequence requirements, design corresponding tooling and work documents to ensure the accuracy of the installation sequence. If the order is not set in advance, it will not proceed.

6. Isolation principle: Use reliable devices to separate unqualified materials from the production line.

7. Copying principle: For some more important detection instruments, in order to ensure their reliability, two can be installed at the same time. This can be used to judge the reliability of their work (whether they are normal) and prevent major consequences due to instrument failure.

8. Hierarchical principle: hierarchical filtering and different identification.

9. Warning principle: For some processes that are error-prone and before good avoidance measures have been figured out, warnings should be used to reduce the possibility of errors.

10. Moderation principle: Reduce the difficulty of the process.

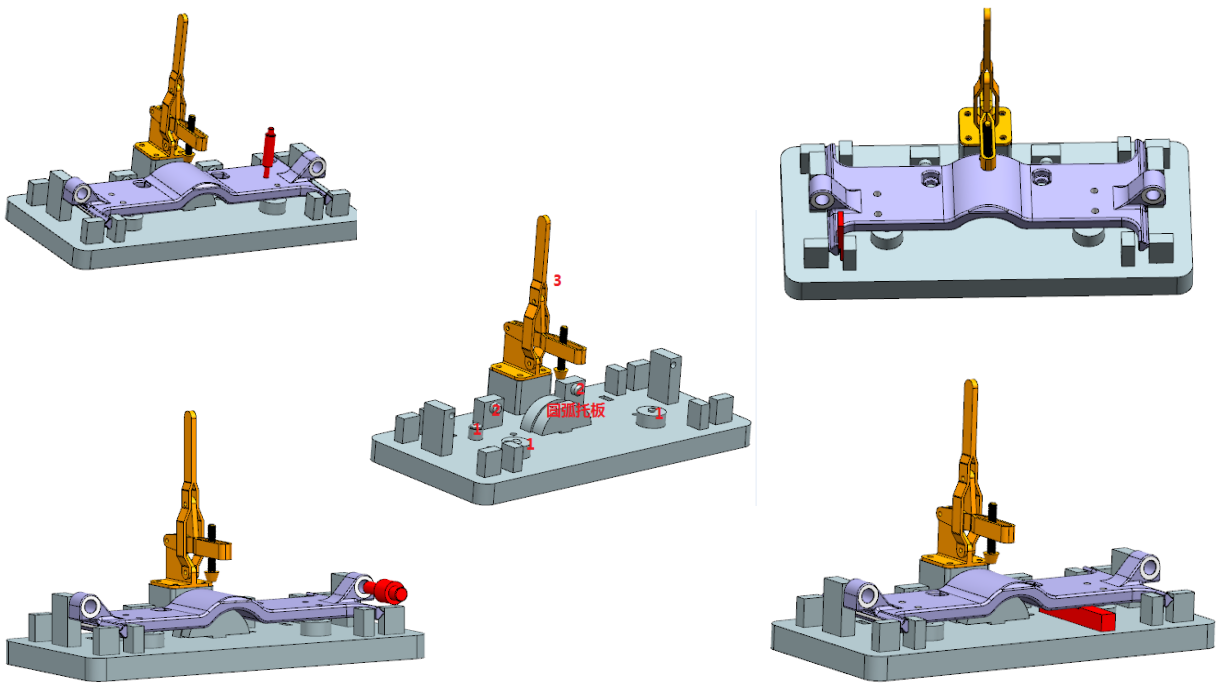

Typical Applications of Error prevention in Factories

During the production process, the factory relies on manual measurement of the machining curvature, position, etc. of the product in the early stage. It is impossible to conduct batch testing and the measurement error is large. Special inspection tools (special error-proofing tools and instruments) are designed to accurately and quickly detect various key Processing dimensions: Key processing dimensions such as arc, height, position, etc. can be detected at the same time.

ILLUSTRATIONS

Kai Quan Dai